Introduction

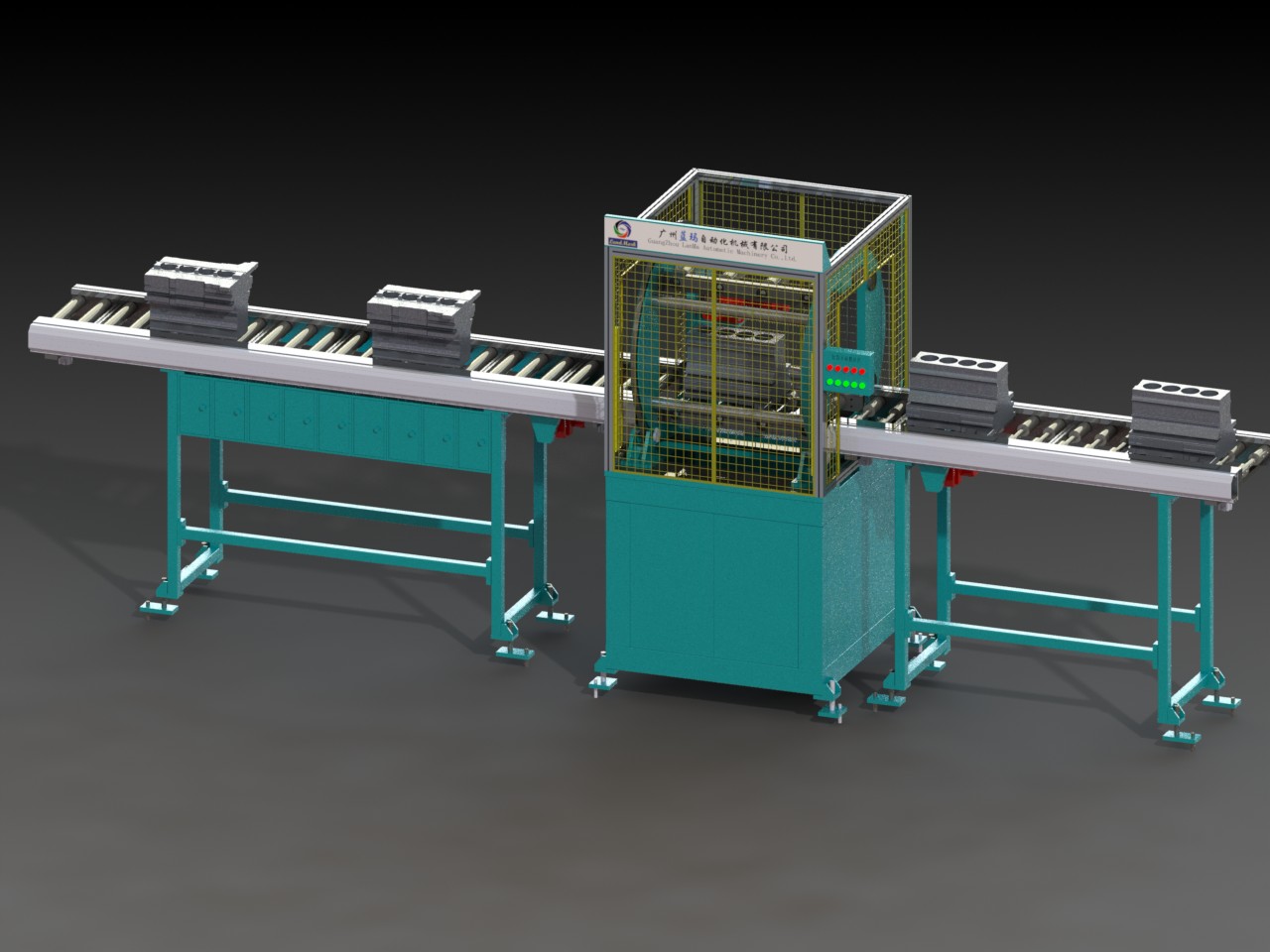

Tighten the automated assembly system

With the rapid development of modern industry, the increasing scale of production, the assembly of increasingly demanding, intelligent automatic tightening system has become an integral part of the assembly line equipment. I developed the intelligent servo tightening system with high reliability, high availability, high precision, can greatly improve production efficiency, reduce production costs, more importantly, to ensure product quality of the assembly, to provide a complete quality control system can be traced back .

A variety of integrated products

A uniaxial tightening machine

2, multi-axis machine tightened up to achieve thirty-two axis.

3, automatic pitch, servo positioning, balance power, tighten the data can be traced. Print or barcode scanning and other functions.

4, can be automatically sent to the screw feature.

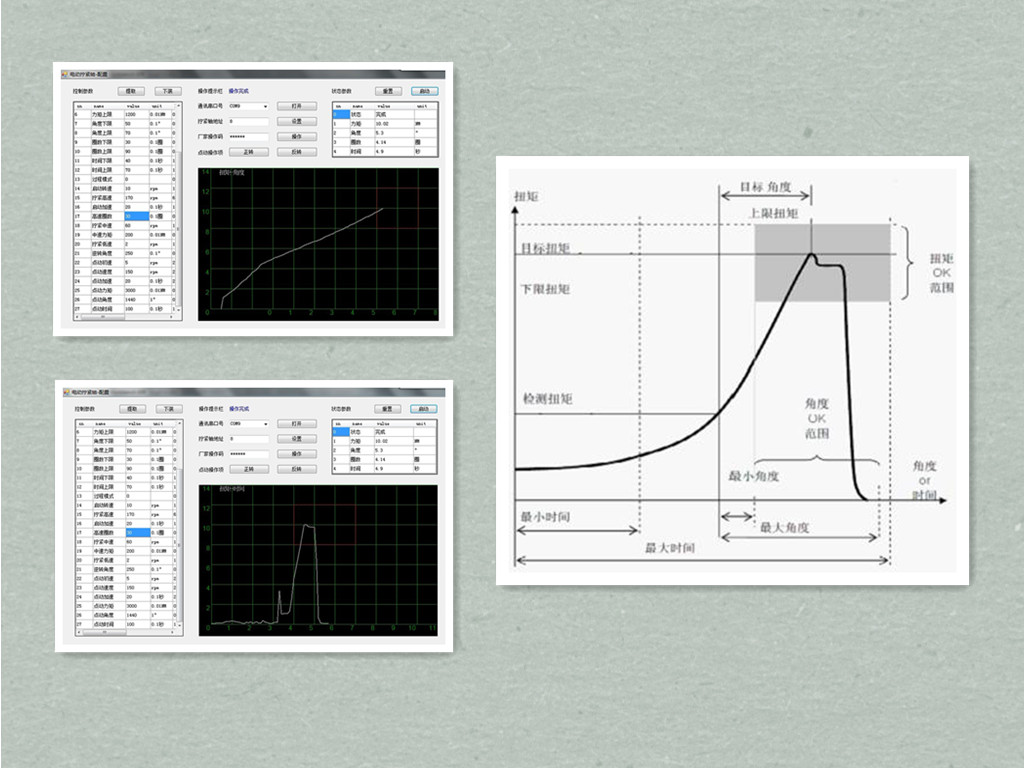

Tighten management software SCI-FS12

2 This is the tightening axis servo dedicated management software, you can make various settings through the computer.

2 parameter configuration can achieve centralized management of data and results, is very convenient.

2 full maintenance functions, a substantial increase Tighten axis servo system convenience.

2 methods for tightening, tightening torque, tightening process and other settings.

2 Tighten monitor the implementation process of tightening the resulting data.

2 can display, print each controller various data stored, or saved to a file.

l Tighten the historical data results

l System error history

l torque curve data: the process of drawing tightening angle - torque, time - the torque curve, etc.

Schematic diagram of the control software and parameters

Product Features

1, support the torque method, angle method, the yield method and other methods tightened.

2, support for multi-axis control mode, single-level system supports up to 32 axes synergistic action, multi-level system of axes unrestricted.

3, space-saving compact design, with a central shaft and the eccentric shaft, can be adapted to different needs.

4, using a high-speed data processing 32Bit CPU.

5, to prevent accidental self-diagnostic function that generated the error.

6, can be installed in any direction, such as vertical, horizontal or inclined.

7, anti-jamming design, the use of electromagnetic shielding devices, and digital technology can be adapted to a more hostile environment.

8, high-quality pre-calibrated torque sensor for accurate tightening.

9, support for bus communication function (ModBus).

10, support for centralized configuration and management.

11, taking into account the previously designed quick maintenance and centralized routing.

12, a user interface has excellent operability.

13, has a rich product lineup that can support bending style, elbow-type and other purposes.

14, using high-performance servo motor, high-speed high-torque tightening torque 800NM, maximum speed 1200rmp.

15, to provide customized services according to customer requirements, providing special structure or greater output torque, speed products.

More Products